2016. Relux: réutiliser des doubles vitrages pour des serres

Design and development of a modular glass kiosque from reclaimed double glazing

Circular economy is about avoiding waste, often by imagining ways that allow resources could flow from one to another. The OSMOS network was eager to find a circular configuration for the thousands of square meters of double glazing windows that a city like Brussels dumps every year… perhaps we also were seduced by the idea of creating comfortable, high-performance winter garden-cum-greenhouse at the origin of our RELUX adventure? Here is a brief account of how the OSMOS network designed and developed a meaningful project: building a beautiful modular glass kiosque from waste…

Circularity challenge

In the 1990s, the city of Brussels underwent real estate a bubble for office space. This lead to staggering overcapacities: today, around 1.2 million square meters of office space are empty in and surrounding the Capital of Europe. By contrast, there is an increasing demand for housing and, albeit to a smaller extent, for more recent, high-quality offices with better energy performance than was produced in the 1990s.

The result: nowadays many office buildings are torn down, are completely retrofitted with triple-glazing or re-vamped as housing units. Organisations like ROTOR* have developed a second-hand market in recirculated objects and materials : design furniture, wooden flooring and other high-value items that sourced from demolition or renovation sites are on display in their brand-new showroom in Rue du Prévérinaire, in Cureghem.

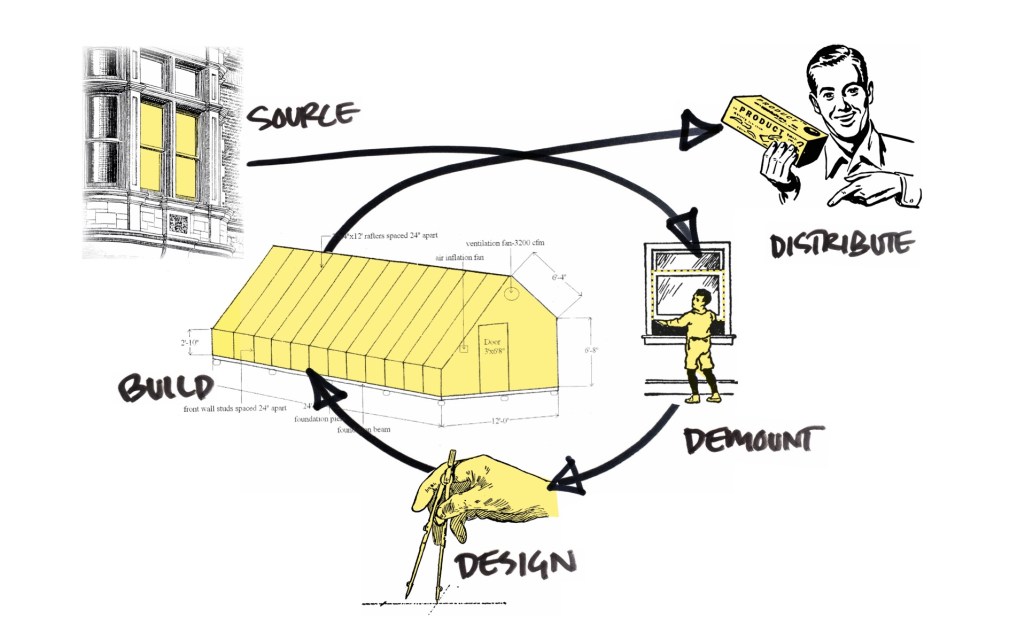

One material that invariably ends up at the junk yard is glazing. The reason for this is that designers tend to first draw a project and then think about where the materials will come from. But once the dimensions of windows are fixed, it is virtually impossible to find the exact same dimensions in another demolition site. To change this, one would have to start designing buildings from the dimensions of windows that happed to be available – a kind of reverse thinking that rarely happens. Result: there is no market for used double glazing.

The concept

This got us thinking about objects that can be made from reclaimed double glazing. Very quickly our Pinterest accounts went berserk on DIY greenhouses that enthusiasts from all over the world have built in backyards, forest, rooftops and vegetable gardens. These people where clearly onto something, but their projects were always one-offs, ad-hoc, experimental and hard to up-scale into a viable commercial activity. All measures are non-standard, all joints and frames have to be recalculated – and the DIY aesthetic à la Mad Max is also not something that most people would like to see in their backyard.

So we wanted to explore better designs for building greenhouses. But we quickly discovered that developing an actual project around this entails much more than bringing in a designer. We also needed to build bridges between many other actors including: the owners and demolition companies sitting on the stock of old windows that they consider as waste; potential users of these greenhouses; builders with machines and technical prowess in order to turn the design into rock-solid reality; entrepreneurs that help defining the economic models that could underlie complete waste-to-resource process; and communicators that document the idea and help spreading it.

All together now

After weeks of spinning the idea, in April 2017 we had it all together. The source: a primary school in Mons that renovates its façades, resulting in hundreds of discarded double glazing panels with similar dimensions. The place: our favourite playground, a massive industrial building in Anderlecht that we use as lab for these experiments and that happens to be a stone throw from ROTOR. The people: a bunch of motivated, talented, likeable students from the Faculty of Architecture of the Université libre de Bruxelles spent one week with us on a transversal circular economy project covering all its aspects, from conception over construction to commercialising and documenting. Plus a potential client from Skyfarms*, an urban agriculture start-up from Brussels interested in offering better greenhouses to their clients.

A messy, but output oriented process

Although we spent several weeks prior to the workshop researching on greenhouses of all types – including a visit to the mind-blowing Serre Royal in Laeken – all important decisions about how to design and develop the RELUX were taken during this one week of intensive workshopping with the students. We divided them into different specialisations (designers, builders, entrepreneurs, communicators) so that we could simultaneously make progress on all aspects of the project. This proved to be essential to avoid a design that fails to meet client expectations… or can’t be built easily.

The final output: the RELUX

The result of a cosy, octagonal kiosque (named the ‘GreeNest’ by the students) in which you can comfortably fit a large table and six people – or 14 running meters of pots with seedlings if that is what you are up to. Each element in the octagon is a module that can easily be moved and transported individually. The structure of the RELUX held up by an elegant metal frame that does not distract from the star of the show: large, 2m x1,50m panes of double glazing. The design is rounded up by a beautiful finish in wood that covers the edges of the windows and lower walls.

Since we finished the RELUX we are often asked why we used double glazing, whereas conventional greenhouses are typically built with low-quality, single-layer panes made out of Plexiglas or simple glazing. The short answer is: because we can! A greenhouse with double glazing has superior thermal and acoustic qualities and stores the heat from the solar radiation much more efficiently. Employing reused double glazing allows the RELUX to achieve this better performance without exploding the costs that new double windows would necessarily imply.

A key advantage from this design is that the RELUX can be used as more than a high-performance greenhouse. From March until May, you can of course use it in this conventional sense and give your seedling two or three month advance over the vegetation outside. From June until September, you can then go on and give your tomatoes or other vegetables a constant, warm microclimate that they like best. But then the growing season is over and most greenhouses in countries like Belgium are abandoned until the next spring. Not the RELUX! Coupled with its splendid looks, the better insulation through double glazing and generous wooden panels turn it into your favourite coffee-drinking spot during autumn and winter: it is a greenhouse, winter garden and orangery in one.